Application industries

Glasses, jewelry,kitchen ware, chassis and cabinet,metal pipe,lamp&lanterns,metal ware,hardware,precision machinery,auto parts,elevator,nameplate,advertisement,electronics,toys and other industries.

Kelebihan Fungsi

1. Kualiti pancaran cahaya yang sangat baik

2. Kelajuan pemotongan tinggi: 2 kali dengan mesin pemotong laser co2 di bawah kuasa yang sama.

3. Kestabilan dan kecekapan penukaran fotoelektrik yang sangat tinggi

4. Sangat rendah menggunakan kos dan kos penyelenggaraan

5. Operasi dan penyelenggaraan produk yang mudah

6. Kesan optik lembut yang sangat kuat: isipadu dan struktur padat

7. Struktur pemanduan ganda gantri, katil alat mesin redaman tinggi, tegar yang baik,

8. Model ini menggunakan pemacu sistem servo AC yang diimport dan sistem penghantaran yang diimport, struktur alat mesin yang bergerak menggunakan transmisi gear dan rak yang diimport, landasan panduan linear untuk membimbing, memastikan peralatan berkelajuan tinggi, berketepatan tinggi dan kebolehpercayaan yang tinggi.

9. Rak dan panduan menggunakan peranti pelindung tertutup sepenuhnya, yang menghalang pergerakan geseran bebas minyak dan pencemaran habuk, meningkatkan penggunaan bahagian penghantaran dan memastikan ketepatan pergerakan alat mesin.

10. Mesin pemotong laser profesional, sistem kawalan cnc, operasi komputer, boleh memastikan kualiti pemotongan, dan lebih mudah untuk kerja pemotongan.

11. Konfigurasi meja swiching automatik, yang memendekkan masa siap sedia, dan secara berkesan meningkatkan kecekapan kerja lebih daripada 30%.

12. Penutup pelindung tertutup sepenuhnya, menggunakan keselamatan. (Model Terlampir)

Ketua Pemotongan Laser Jerman yang diimport :Selection of Germany Laser cutting head brings Z axis servo function. It’s servo sensor adopts capacitive sensing sensor monitoring and provide cutting auto focusing features of high sensitivity, stability and fastness. With characteristics, it makes the fixed length cutting head body install optical lenses with different focal lengths so that the focus and the nozzle height can be adjusted flexibly.

Consumption Materials Sheet Reference

Nombor | Bahan | Cutting Carbon Steel Plate(1mm) | Cutting Stainless Steel or Aluminum Plate(1mm) | |

| Bottle Nitrogen | Liquid Nitrogen | |||

| 1 | Penggunaan kuasa | USD 0.58 /hour | ||

| 2 | Laser gas consumption | 0 | ||

| 3 | Cutting auxiliary gas consumption | USD1.1 / hour | USD9.5 / hour | USD4.7/ hour |

| 4 | Cermin Perlindungan | 1 month / pc | ||

| 5 | Focusing lens consumption | 1 month/pc | ||

| 6 | Cutting nozzle consumption | 1 month/ pc | ||

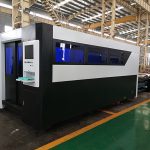

Butiran Cepat

Permohonan: Laser Cutting

Keadaan: Baru

Jenis Laser: Serat Laser

Bahan yang berkenaan: Logam

Ketebalan pemotongan: 20mm

Cutting Area: 3500x1500mm

Cutting Speed: 18m/min

CNC atau Tidak: Ya

Mod Penyejukan: Penyejuk Air

Control Software: automatic control

Format grafik yang disokong: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Persijilan: CE, ISO

Perkhidmatan selepas jualan yang disediakan: Jurutera yang tersedia untuk jentera perkhidmatan di luar negara

500w fiber laser cutting machine: without consumptive materials

CE and ISO: Excellent Service

Parameter teknikal

Jenis Laser | Laser Fiber Asli yang diimport | ||||

| Panjang gelombang Laser | 1060nm | ||||

| Laser Maksimum Kuasa | 500W | 1000W | 2000W | 3000W | 4000W |

| Maks. Ketebalan memotong | ≤8mm | ≤12mm | ≤16mm | ≤18mm | ≤20mm |

| Jumlah Kuasa Penggunaan | <14KW | <18KW | <22KW | <26KW | <30KW |

| Saiz Kerja | |||||

| Kelajuan max.cutting | 0-30m / min (Bergantung pada bahan dan ketebalan) | ||||

| Ketepatan Orientasi X, Y, Z Paksi | ≤ ± 0.05mm / m | ||||

| X, Y, Z Axis Repeat Precision | ≤ ± 0.03mm / m | ||||

| Lebar baris min | ≤0.15mm | ||||

| Kelajuan Running Kosong Maksimum | 120m / min | ||||

| Cara memandu | Motor servo yang diimport | ||||

| Cara penghantaran | Y axis import gear rack double driver, X-axis diimpal bola skru | ||||

| Beban Max Kerja | 1600 KGS | ||||

| Sistem penyejuk | Penyejuk Air | ||||

| Masa kerja yang berterusan | 24 jam | ||||

| Suhu alam sekitar | 0-35 ° C | ||||

| Keperluan kuasa | 380V / 3 Fasa / 50Hz atau 60Hz | ||||

| Keperluan kuasa Saiz luar (L * W * H) | 4500x2000x1800mm | ||||