Kelebihan Fungsi

1. Kualiti pancaran cahaya yang sangat baik

2. Kelajuan pemotongan tinggi: 2 kali dengan mesin pemotong laser co2 di bawah kuasa yang sama.

3. Kestabilan dan kecekapan penukaran fotoelektrik yang sangat tinggi

4. Sangat rendah menggunakan kos dan kos penyelenggaraan

5. Operasi dan penyelenggaraan produk yang mudah

6. Kesan optik lembut yang sangat kuat: isipadu dan struktur padat

7. Struktur pemanduan ganda gantri, katil alat mesin redaman tinggi, tegar yang baik,

8. Model ini menggunakan pemacu sistem servo AC yang diimport dan sistem penghantaran yang diimport, struktur alat mesin yang bergerak menggunakan transmisi gear dan rak yang diimport, landasan panduan linear untuk membimbing, memastikan peralatan berkelajuan tinggi, berketepatan tinggi dan kebolehpercayaan yang tinggi.

9. Rak dan panduan menggunakan peranti pelindung tertutup sepenuhnya, yang menghalang pergerakan geseran bebas minyak dan pencemaran habuk, meningkatkan penggunaan bahagian penghantaran dan memastikan ketepatan pergerakan alat mesin.

10. Mesin pemotong laser profesional, sistem kawalan cnc, operasi komputer, boleh memastikan kualiti pemotongan, dan lebih mudah untuk kerja pemotongan.

11. Konfigurasi meja swiching automatik, yang memendekkan masa siap sedia, dan secara berkesan meningkatkan kecekapan kerja lebih daripada 30%.

12. Penutup pelindung tertutup sepenuhnya, menggunakan keselamatan. (Model Terlampir)

Ketua Pemotongan Laser Jerman yang diimport

Pemilihan kepala pemotong laser Jerman membawa fungsi servo paksi Z. Penderia servonya mengguna pakai pemantauan penderia penderiaan kapasitif dan menyediakan ciri pemfokusan auto pemotongan dengan kepekaan tinggi, kestabilan dan kepantasan. Dengan ciri-ciri, ia menjadikan badan kepala pemotong panjang tetap memasang kanta optik dengan jarak fokus yang berbeza supaya fokus dan ketinggian muncung boleh dilaraskan secara fleksibel.

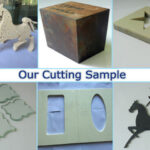

Mesin pemotong laser serat contoh persembahan

1) Bahan Permohonan:

Peralatan Pemotongan Laser Serat sesuai untuk pemotongan logam dengan lembaran keluli tahan karat, plat keluli ringan, lembaran keluli karbon, plat keluli aloi, lembaran keluli musim bunga, plat besi, besi galvanis, lembaran galvanis, plat aluminium, lembaran tembaga, lembaran tembaga, plat tembaga, Plat Perak, Plat Titanium, Lembaran Logam, Plat Logam, Tiub dan Paip, dan lain-lain

2) Industri Aplikasi:

The Mesin Pemotongan Serat Laser digunakan secara meluas dalam pembuatan Billboard, Pengiklanan, Tanda-tanda, Logam, Surat Logam, Surat LED, Ware Dapur, Surat Pengiklanan, Pemprosesan Logam Lembaran, Komponen Logam dan Bahagian, Ironware, Keratan Panel Lif, Perkakasan, Bahagian Auto, Bingkai Kaca, Bahagian Elektronik, Nameplates, dll.

Butiran Cepat

Permohonan: Laser Cutting

Keadaan: Baru

Jenis Laser: Serat Laser

Bahan yang berkenaan: Logam

Pemotongan Tebal: 0-30mm

Kawasan pemotongan: 1300 * 2500mm

Kelajuan Keratan: 0-40000mm / min

CNC atau Tidak: Ya

Mod Penyejukan: Penyejuk Udara

Perisian Kawalan: Leetro

Format grafik yang disokong: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Tempat asal: Anhui, China (tanah besar)

Nama Jenama: accurl

Persijilan: CE, ISO

Perkhidmatan selepas jualan yang disediakan: Jurutera yang tersedia untuk jentera perkhidmatan di luar negara

Nama: Mesin Pemotong Laser CNC

Nama produk: kilang mesin pemotong laser gentian logam

Kuasa laser: 500W / 1000W / 2000W / 3000W

Tiub laser: penjana laser gentian IPG atau Raycus

Kata kunci: Pemotong Laser Fabrik

Fungsi: Keratan Bahan Logam

Jenis:Pemesinan Laser

Model: APEX-1325

Warna: Biru

Kawasan kerja: 1300mmX2500mm

perkhidmatan kami

1.Guarantee selama 3 tahun.

2. Penyelenggaraan secara percuma selama 3 tahun.

3. Kami akan menyediakan bahagian-bahagian yang boleh dibelanjakan pada harga agensi.

4.24 jam perkhidmatan dalam talian, sokongan teknikal percuma.

5.Machine telah diselaraskan sebelum penghantaran, disk operasi dimasukkan dalam penghantaran. Sekiranya terdapat sebarang pertanyaan lain, sila beritahu saya.

6. Kami mempunyai arahan manual dan CD (Video Panduan) untuk pemasangan perisian, operasi dan penggunaan dan penyelenggaraan mesin.

Mesin pemotong laser serat parameter

| Jenis Laser | Laser Fiber Asli yang diimport | ||||

| Panjang gelombang Laser | 1060nm | ||||

| Laser Maksimum Kuasa | 500W | 1000W | 2000W | 3000W | 4000W |

| Maks. Ketebalan memotong | ≤8mm | ≤12mm | ≤16mm | ≤18mm | ≤20mm |

| Jumlah Kuasa Penggunaan | <14KW | <18KW | <22KW | <26KW | <30KW |

| Saiz Kerja | 1500X2500mm / 1500X3000mm / 2000X4000mm | ||||

| Kelajuan max.cutting | 0-30m / min (Bergantung pada bahan dan ketebalan) | ||||

| Ketepatan Orientasi X, Y, Z Paksi | ≤ ± 0.05mm / m | ||||

| X, Y, Z Axis Repeat Precision | ≤ ± 0.03mm / m | ||||

| Lebar baris min | ≤0.15mm | ||||

| Kelajuan Running Kosong Maksimum | 120m / min | ||||

| Cara memandu | Motor servo yang diimport | ||||

| Cara penghantaran | Y axis import gear rack double driver, X-axis diimpal bola skru | ||||

| Beban Max Kerja | 1600 KGS | ||||

| Sistem penyejuk | Penyejuk Air | ||||

| Masa kerja yang berterusan | 24 jam | ||||

| Suhu alam sekitar | 0-35 ° C | ||||

| Keperluan kuasa | 380V / 3 Fasa / 50Hz atau 60Hz | ||||

| Keperluan kuasa Saiz luar (L * W * H) | 4500x2000x1800mm | ||||