Penerangan Produk Terperinci

| Nombor model: | ECO-FIBER-1530-6KW ACCURL | Julat Kerja: | 1500x3000mm |

|---|---|---|---|

| Jenis Laser: | Amerika Syarikat Raycus Fiber YLS-6Kw | Penghantaran: | Taiwan YYC Gear And Rack |

| Ketua Laser: | Switzerland Raytools Auto-berikut | Sistem yang didorong oleh jadual: | Jepun Yaskawa Servo Motor & Sistem Pemanduan |

| Jumlah Penggunaan Kuasa: | Perisian Pemotongan Laser Profesional Accurl Laser | Kata kunci: | Mesin Pemotong Laser Dalam Logam |

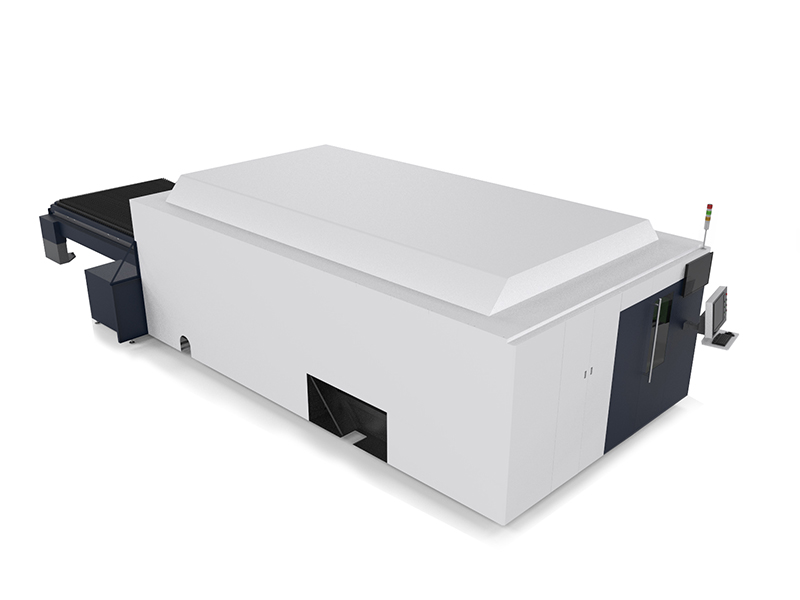

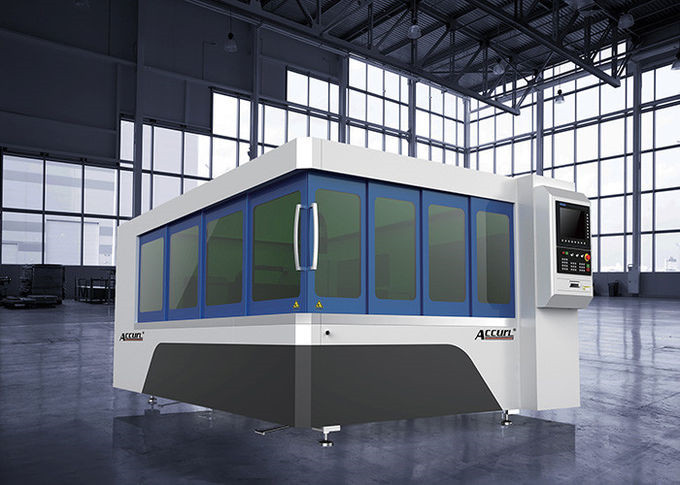

Mesin Pemotong Laser 6KW dalam logam Aloi Aluminium 16 mm dengan Kuasa Laser Fiber Raycus

pengenalan produk

Laser Fiber ACCURL membawa penyelesaian kos efektif, penyelenggaraan rendah, kos operasi rendah dan mesra alam kepada organisasi anda. Mesin laser gentian kami menyediakan pemotongan dan toleransi yang berkualiti dengan kehilangan produktiviti minimum antara pekerjaan, menyamai pulangan pelaburan yang lebih tinggi.

• Dikilangkan oleh orang yang menggunakan mesin mereka sendiri

• Pancaran laser dihantar melalui kabel gentian optik dan bukannya dengan cermin dan tiub saluran yang mengakibatkan kehilangan kuasa yang boleh diabaikan.

• Sumber cahaya laser mempunyai jangka hayat lebih daripada tiga kali ganda jangka hayat laser CO2 yang setara.

• Kelajuan pemotongan yang lebih tinggi mungkin

• Jadual boleh dipertukarkan dua kali membolehkan pemuatan dan pemuatan lebih cepat, mengurangkan masa henti

• Panjang gelombang laser adalah sepersepuluh daripada laser CO2

• Pengurangan pembolehubah pemotongan atau pengetahuan puak

• Serat Laser sangat cekap, sama dengan penggunaan tenaga yang sangat rendah

• Kos operasi yang rendah, kos tenaga yang dikurangkan, tiada gas laser diperlukan untuk menghasilkan pancaran

• Kelenturan pemotongan yang tinggi (Keluli, Keluli Tahan Karat, Tembaga, Tembaga, Titanium, Aluminium, dan banyak lagi)

• Sangat sedikit bahan habis pakai

PERALATAN STANDARD

• Rangka mesin laser melegakan tekanan

• Sistem dwi palet auto-tukar

• Sumber cahaya

• Penyejuk

• Sistem CAD/CAM Radan atau Lantek

• Sistem Pemacu Rak & Pinion Ketepatan (Dibuat di Jerman)

• 3 kanta pelindung bawah

• 5 muncung setiap satu daripada berikut: (1.0mm, 1.2mm,1.5mm, 2.0mm, 2.5mm, 3.0mm)

• 3 Penyesuai Muncung Seramik

• Sistem muncung yang ditentukur secara automatik

• Kanta dengan 5.9” Panjang Fokus

• Sistem Pengumpulan Slag Pintar/ Penghantar Cip

• Sistem Penghantaran Rasuk Gentian (Kabel Gentian)

• Beroperasi dengan kedua-dua gas N2 dan O2 (pemotongan).

• Sistem Penjajaran Kedudukan Rumah

• Pemilih Gas Bantu

• Fungsi NC Tekanan Gas Tambahan

• Amaran Pantulan Auto

• Lampu Kerja

• Lampu Penunjuk Amaran

• Kit Pembersihan Kanta

• Alat Penyingkiran dan Pelarasan

• Plat Tanah

• Manual Pengguna dalam bahasa Inggeris

PERALATAN OPTIONAL

• Pemacu Linear

• Unit Pengumpulan Habuk

• Cermin Mata Operator Tambahan

• Kanta dengan 7.874” Panjang Fokus

• Sistem pemuatan & pemunggahan helaian

• Sistem Automasi & Penyimpanan

• Penukar Muncung Automatik

• Saiz meja tersuai

• Sumber cahaya laser laser sehingga 6 kW

• Penghalang keselamatan yang ringan

• Penghawa dingin untuk panel elektrik

• Metalix, Almacam dll. Perisian CAD/CAM

• Sensor LCM (monitor potong laser) untuk pengesanan pierce dan kawalan cut loss

PEMULIHAN KEPUTUSAN

• Pancaran laser dihantar ke kepala pemotong dengan kabel gentian optik.

• Kabel gentian optik dipasang pada input kepala pemotong.

• Laser dihantar ke unit pemfokusan selepas dijajarkan dalam kolimator.

• Pancaran laser ditetapkan kepada fokus yang diingini menggunakan kanta dalam unit pemfokus.

• Kaca perlindungan melindungi kanta daripada zarah yang disebabkan oleh operasi pemotongan.

• Sisipan sensor adalah sebahagian daripada sistem kawalan ketinggian dan membantu melaraskan jarak antara bahan dan kepala pemotong.

• Kawalan ketinggian disemak dengan penderia paling tepat di pasaran. Ini membantu menghasilkan potongan yang lebih baik.

• Fungsi utama seramik adalah untuk melindungi kepala pemotong.

• Muncung digunakan untuk mengawal gas bantuan. Ia juga merupakan sebahagian daripada sistem kawalan kapasitif.

Konfigurasi bagi Mesin memotong laser

Platform mekanikal: penutup, rel, tapak, terdiri daripada bingkai reflektif dan bahagian mekanikal lain;

Drivetrain: empat seimbang dengan tiga panduan linear berketepatan tinggi yang diimport, tiga skru bola berketepatan tinggi, tali pinggang, tiga motor stepper dan beberapa gear;

Sistem tambahan: Terdapat pam air penyejuk yang beredar, pemampat tiupan, kipas ekzos asap;

Sistem optik: tiub laser, bekalan kuasa laser, tiga cermin pantulan logam dan komponen kepala fokus.

Kelebihan

1) kualiti rasuk yang cemerlang: diameter fokus yang lebih kecil dan kecekapan kerja yang tinggi, berkualiti tinggi.

2) kelajuan pemotongan yang tinggi: Kelajuan pemotongan lebih dari 20m / min

3) Stabil berjalan: Mengguna pakai laser serat import dunia atas, prestasi stabil, bahagian kunci dapat mencapai 100,000 jam;

4) Kecekapan tinggi untuk penukaran fotoelektrik: Bandingkan dengan mesin pemotong laser CO2, potongan laser serat optik mempunyai tiga kali kecekapan penukaran fotoelektrik

5) Kos rendah & Tenancy utama: Simpan tenaga dan melindungi persekitaran. Kadar penukaran fotoelektrik adalah sehingga 25-30%. Penggunaan kuasa elektrik yang rendah, hanya kira-kira 20% -30% mesin pemotong laser CO2 tradisional. Penghantaran talian gentian tidak perlu mencerminkan kanta, menjimatkan kos penyelenggaraan;

6) Operasi yang mudah: penghantaran talian gentian, tiada penyesuaian laluan optik;

7) Super optik kesan optik: Reka bentuk padat, mudah untuk keperluan pembuatan fleksibel.

Parameter Techincal

| Model | ECO-FIBER 3015 / 6KW | |

| Unit Kawalan CNC | FAGOR 8060 CNC System | |

| Paksi X (Rak & Pinion) | 3000 mm | |

| Paksi Y (Rak & Pinion) | 1500 mm | |

| Paksi Z (Bola skru) | 100 mm | |

| Kapasiti pemotongan maksimum | Stee lembut | 32 mm |

| Keluli tahan karat | 16 mm | |

| Aluminyum | 16 mm | |

| Dimensi kerja | 1525 x 3050 mm | |

| Rapuh melintasi (paksi X dan Y) | 105 m / min | |

| Pecutan | 2.5G (25m / s2) | |

| Kelajuan vektor | 148 m / min | |

| Ketepatan kedudukan mutlak | ± 0.08 mm | |

| Kebolehulangan (paksi X dan Y) | ± 0.03 mm | |

| Maks. had muatan | 2450 kg | |

| Sistem CNC Prestasi Tinggi | FAGOR 8060 dari Sepanyol Jenama | |

| Kuasa Laser | IPG YLS-6 kW dari Jerman | |

| Motor Servo Prestasi Berkelajuan Tinggi | FAGOR dari Sepanyol Jenama | |

| Ketua Pemotongan Laser | PRECITEC dari Jerman | |

| Motoreducer | STOBER dari Jerman | |