Penerangan Produk

Product Application:

Furniture ,Medical Device,Fitness Equipment,Oil Exploration,Display Shelf,Farm Machinery,Bridge,Boating,Structure Parts.

Applicable type for tube:

Specially for round,square,rectangular,oval,waist round tube and other metal pipes

Bahan yang Berkenaan:

Carbon Steel, Stainless Steel, Aluminum, Brass,Copper,Galvanized Steel.

Automatic Bundle Loader Steel Square Pipe Making Machine | |||

Pipe type | round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc (standard),Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

Pipe length | 6000mm | ||

Pipe size | Φ20-200mm | ||

Ulang ketepatan kedudukan | ± 0.03mm | ||

Ketepatan kedudukan | ± 0.05mm | ||

Fiber laser source | 1000w/1200w/2000w/2500w/3000w | ||

Kelajuan kedudukan | Max 90m/min | ||

Chuck rotate speed | Max 105r/min | ||

Pecutan | 1.2g | ||

Cut Acceleration | 1g | ||

Bundle size | 800mm*800mm*6000mm | ||

Bundle weight | Max 2500kg | ||

Bekalan kuasa elektrik | AC380V 50/60Hz 3PH | ||

Ciri-ciri utama

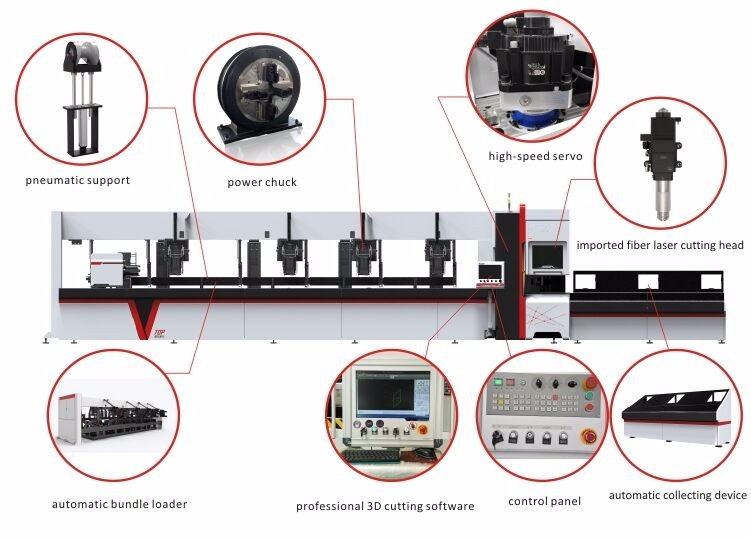

AUTOMATIC BUNDLE LOADER SYSTEM

1,Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention. Other shapes pipe can be semi-automatic feeding artificially

2,Max loading bundle 800x800mm

3,Max loading bundle weight 2500kg

4,The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

5,The tape support frame for easy removal

6,Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

7,The pneumatic system components used AirTAC or other more high-end brand, PLC control, sensors and other selected Omron, Schneider and other well-known brands. Ensure the stability of the system and export standard

Terperinci

Bahagian Mesin

Name: Automatic loading mechanism

1.The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

2.Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

Bahagian Mesin

Nama: Peranti mengumpul automatik

1. sokongan peningkatan automatik, menerima tiub dan skrap ke dalam bakul

2. Sokongan skala visual boleh menyesuaikan diameter sokongan dengan cepat mengikut diameter pipa

3. peranti penyejukan sokongan laras berskala optik menjimatkan masa makan, memastikan konsentrisiti, menghalang swing logam

Ciri-ciri utama

Name: Power chuck

1.Chuck dengan menukar laluan gas, biasa empat rahang hubungan chuck, pengoptimuman kuasa stroke Cheng chuck berganda bertindak.

2.Mempersikan diameter yang berbeza, bentuk paip dalam jarak perjalanan (stroke bilateral 80mm), tidak perlu menyesuaikan persediaan mudah rahang dan berpusat.

3.easy switching of different diameters, a substantial saving setup time..

Bahagian Mesin

Name: Pneumatic support

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe..

Ciri-ciri utama

Name: Integration bed

1. Sebagai katil yang dikimpal secara keseluruhan, panjang keseluruhan 8 meter.

2. Tempat tidur integrasi dapat memastikan kepekatan peralatan, pemasangan menegak, ketepatan dengan lebih pantas dan cekap.

3.The whole structure is compact precision

Butiran Cepat

Keadaan: Baru

Jenis Laser: Serat Laser

Bahan yang berkenaan: Logam

Cutting Thickness: Depends on power source

Kawasan Keratan: tiub panjang 6m, 8m; diameter tiub 20-300mm

Cutting Speed: depending on materials and fiber power

CNC atau Tidak: Ya

Mod Penyejukan: Penyejuk Air

Perisian Kawalan: Cypcut

Format grafik yang disokong: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Tempat asal: Anhui, China (tanah besar)

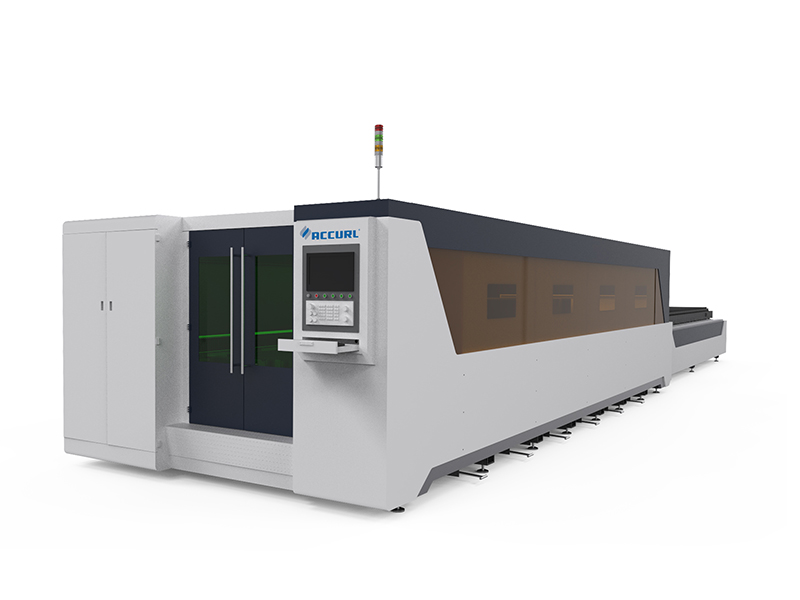

Jenama: ACCURL

Persijilan: CE

Perkhidmatan selepas jualan yang disediakan: Jurutera yang tersedia untuk jentera perkhidmatan di luar negara

Model: P2060A

Repeat position accuracy: ±0.03mm

Position accuracy: ±0.05mm

Fiber laser source: 1000w/1200w/2000w/2500w/3000w

Position speed: Max 90m/min

Acceleration: 1.2g

Electric power supply: AC380V 50/60Hz 3PH