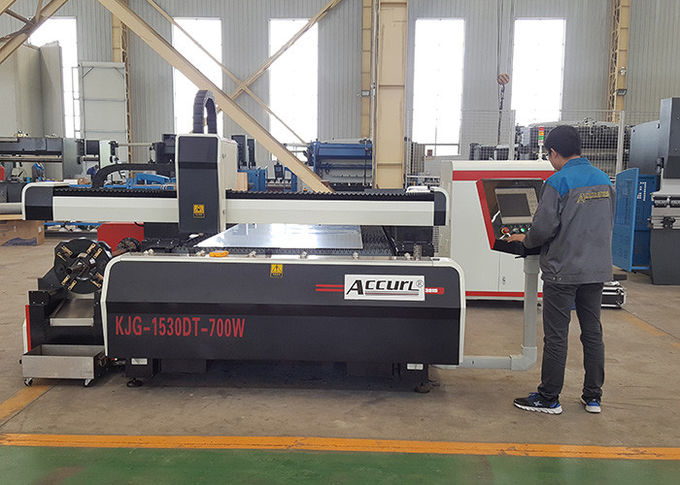

Penerangan Produk Terperinci

| Nombor model: | KJG-1530DT-700W ACCURL | Julat Kerja: | 1500x3000mm |

|---|---|---|---|

| Jenis Laser: | Fiber IPG USA YLS-700w | Panduan Linear: | Taiwan HIWIN |

| Penyejuk: | S & A Untuk Sumber Laser Dan Kepala Pemotongan | Kata kunci: | Harga Mesin Pemotong Laser |

Harga Mesin Pemotong Laser ACCURL 700w untuk Pemotongan Laser Keluli Karbon 8mm

pengenalan produk

Pasukan ACCURL kami kini memperkenalkan generasi terbaharu dalam tiub dan teknologi pemprosesan profil - sistem pemotongan tiub laser serat. Inovasi teknologi telah membawa kita Siri KJG Pintar. Dengan kebolehpercayaan yang luar biasa dan kualiti rasuk yang tinggi, mesin pemotong laser serat kami terus menjadi pemimpin di antara pertandingan ini.

Accurl @ Fiber Lasers membawa anda kos efektif, penyelenggaraan yang rendah, kos operasi yang rendah, penyelesaian mesra alam kepada organisasi anda. Kami menghantar mesin yang memotong dan menerima toleransi dengan kehilangan produktiviti kecil di antara pekerjaan, menyamai pelaburan pulangan yang lebih tinggi. Mesin pemotong laser gentian kami dibangunkan dan dijual berdasarkan kriteria ini.

PERALATAN STANDARD

• mesra pengguna Cyproc Windows CAD / CAM unit kawalan CNC.

• ciri lunique:

• Sangat mudah dikendalikan.

• Pemasangan yang cepat dan mudah.

• Kos pelaburan dan operasi yang rendah.

• Penyelesaian yang paling cekap kos untuk setiap keperluan.

• Laluan rasuk fleksibel

• Kuasa keluaran yang tinggi

• Kualiti optik yang tinggi

• Sehingga 0 pemotongan lebih pantas

• Kecekapan plag dinding tinggi (>% 30)

• Tembaga, keupayaan memotong tembaga

• Ketua memotong Raytools maju (dengan letupan salib udara).

• Prestasi tinggi dan rak ketepatan tinggi dan sistem pinion.

PERALATAN OPTIONAL

• Sistem CNC 8055 CNC (Servo motor)

• Meja Shuttle dan Bilik Bersih

• Saiz meja 1500x4000mm

• Saiz meja 2000x4000mm

• Sistem pemotongan paip (φ220mm / 3000mm)

• Pemotongan Ketua dari PRECITEC- Manual (500w-1500w)

• Amerika Syarikat.IPG / nLIGHT / China.Raycus Fiber Laser Power (500w-2kw)

Konfigurasi mesin pemotong laser

Platform mekanikal: penutup, rel, tapak, terdiri daripada bingkai reflektif dan bahagian mekanikal lain;

Drivetrain: empat seimbang dengan tiga panduan linear berketepatan tinggi yang diimport, tiga skru bola berketepatan tinggi, tali pinggang, tiga motor stepper dan beberapa gear;

Sistem tambahan: Terdapat pam air penyejuk yang beredar, pemampat tiupan, kipas ekzos asap;

Sistem optik: tiub laser, bekalan kuasa laser, tiga cermin pantulan logam dan komponen kepala fokus.

Kelebihan mesin pemotong logam laser gentian

(1) laser gentian - Kecekapan penukaran cahaya yang tinggi, kecekapan penukaran melebihi 30%, dengan laser gentian kuasa kecil tanpa penyejuk, penyejuk udara, boleh menjimatkan kuasa di tempat kerja, penjimatan kos operasi, produktiviti tertinggi;

(2) laser menjalankan kuasa, tanpa menjana laser gas tambahan yang mempunyai kos operasi dan penyelenggaraan yang paling rendah;

(3) Laser gentian menggunakan reka bentuk modular dan redundan semikonduktor, rongga resonan tanpa kanta optik, tiada masa permulaan, dengan kelebihan bebas pelarasan, bebas penyelenggaraan, kestabilan tinggi, mengurangkan kos bahagian dan masa penyelenggaraan, yang tidak dapat ditandingi oleh laser konvensional ;

(4) panjang gelombang keluaran laser gentian 1.06 mikron, adalah panjang gelombang CO2 1/10, keluaran kualiti rasuk, ketumpatan kuasa tinggi, sangat kondusif untuk penyerapan bahan logam, dengan keupayaan pemotongan dan kimpalan yang sangat baik, supaya kos pemprosesan minimum ;

(5) keseluruhan laluan penghantaran gentian optik mesin pemotong laser, dan oleh itu tiada sistem optik cermin kompleks, laluan cahaya adalah mudah, struktur stabil, laluan cahaya luaran bebas penyelenggaraan;

(6) kepala pemotong mengandungi kaca pelindung, sangat berharga dan jarang memfokuskan penggunaan bahan habis pakai cermin;

(7) dengan mengeksport cahaya gentian optik, supaya reka bentuk sistem mekanikal menjadi sangat mudah dan sangat mudah untuk disepadukan dengan robot atau jadual berbilang dimensi;

(8) laser tambah pengatup Anda boleh menghantar mesin Multi, melalui pembahagi gentian optik, berpecah kepada berbilang serentak berbilang, mudah untuk mengembangkan fungsi, mudah untuk menaik taraf.

Pembungkusan & Penghantaran

1. kes kayu kami adalah selepas rawatan pengasapan.Tidak perlu pemeriksaan kayu, menjimatkan masa penghantaran.

2. Semua alat ganti mesin diliputi oleh beberapa bahan lembut, terutamanya menggunakan bulu mutiara.

3. Outmost adalah kes kayu dengan acuan tetap.

4. Bahagian bawah kes kayu mempunyai baja besi yang kukuh, mudah untuk Penanganan dan pengangkutan.

Perkhidmatan kami

Perkhidmatan Pra Jualan

• Penyelesaian teknikal.

• Kerja mesin pengesahan video dalam talian.

• Sampel pemotongan disediakan oleh DHL.

Perkhidmatan selepas jualan

• Melatih cara memasang mesin, melatih cara menggunakan mesin.

• Jurutera sedia untuk menservis jentera di luar negara.

| Model | KJG-1530 / IPG 700w | |

| Kapasiti pemotongan maksimum | Keluli lembut | 8mm |

| Keluli tahan karat | 3mm | |

| Aluminyum | 2.5mm | |

| Tembaga | 1.5mm | |

| Laser Power | YLR-700Watt | |

| Kelajuan berjalan maks | 40 / min | |

| Dimensi kerja | 1500 x 3000mm | |

| Rapuh melintasi (paksi X dan Y) | 105 m / min | |

| Pecutan | 1.2G (12m / s2) | |

| Ketepatan kedudukan mutlak | ± 0.03 mm | |

| Maks. had muatan | 1550 kg | |

| Pengangkut peluntur | 1000 m3 / jam | |

| Ketua Pemotongan Laser | RayTools BM110 dari Switzerland | |

| Kadar suapan | Boleh diprogramkan sehingga 30 m / min. | |

| Bahan Terapan | Keluli tahan karat nipis, Keluli tahan karat, Aluminium, Plat tembaga | |