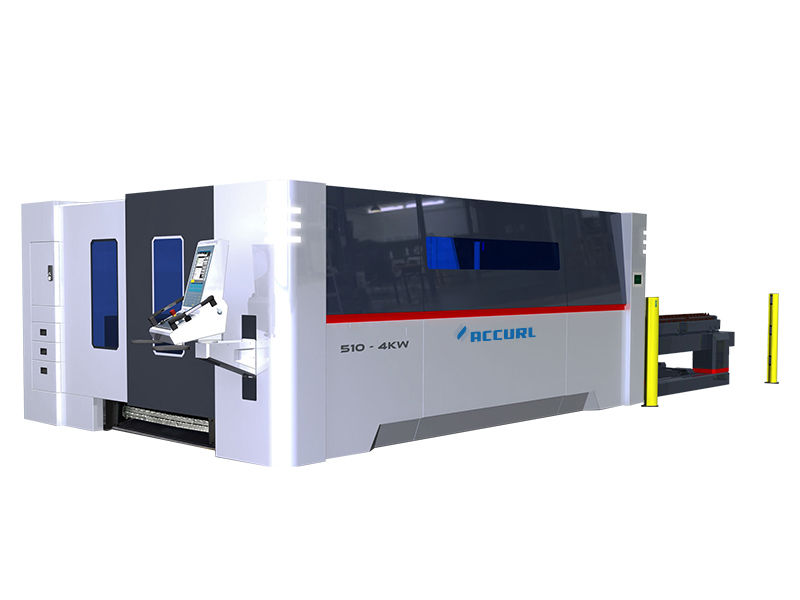

Permohonan Produk

Dengan kawasan kerja 1500mm x3000mm, F3015 ialah model asas dan paling ekonomi untuk ACCURL3015. Digunakan secara meluas dalam pemprosesan papan pengiklanan, struktur plat logam, pengeluaran bahtera elektrik Hv/lv, bahagian jentera tekstil, peralatan dapur, kereta, jentera, lif, bahagian elektrik, kepingan gegelung spring, alat ganti talian kereta bawah tanah, dll.

SPESIFIKASI UNTUK ACCURL3015 MESIN PEMOTONG LOGAM LASER FIBER | |||

Ketua laser | Kepala Laser Fokus Auto BodorGenius | ||

Sumber Laser | IPG/Maxphotonics | ||

Kawasan kerja | 1500 * 3000mm | ||

Laser Power | 500w/700w/800w/1000w/1500w/2000w/2500w/3000w/4000w | ||

Cara Penyejukan | Penyejuk Air | ||

Sistem kawalan | BodorPro | ||

Kelajuan Pemotongan Maks | 35m / min | ||

Ketepatan | Ketepatan Kedudukan: 0.03mm. Ketepatan Kedudukan semula: 0.02mm | ||

Sistem pemacu | Jepun YASKAWA Servo Motor | ||

Penghantaran | Rel persegi HIWIN perak Taiwan, rak gear Taiwan YYC | ||

galas | Galas NSK Jepun | ||

Komponen elektrik | Komponen elektrik Schneider Perancis | ||

Komponen pneumatik | Komponen pneumatik SMC Jepun | ||

Saiz mesin + berat | 4550*2300*2000mm, Selepas pakej, berat 3000kg | ||

Pecutan maksimum | 1.5G | ||

Bahagian lain | Sistem pelinciran automatik + tolok tekanan + gogal pelindung laser + Kawalan WIFI + panel kawalan dan lain-lain. | ||

Ciri-ciri utama

1. Kualiti Laluan Cemerlang: Titik laser yang lebih kecil dan kecekapan kerja yang tinggi, berkualiti tinggi.

2. Kelajuan Keratan Tinggi: kelajuan pemotongan adalah 2-3 kali daripada kuasa pemotong laser CO2 yang sama.

3. Stabil Running: mengadopsi laser serat import dunia teratas, prestasi yang stabil, bahagian kunci boleh mencapai 100,000 jam;

4. Kecekapan Tinggi untuk penukaran fotoelektrik: Bandingkan dengan mesin pemotong laser CO2, mesin pemotong laser serat mempunyai kecekapan penukaran fotoelektrik tiga kali ganda.

5. Kos Rendah: Hemat tenaga dan melindungi alam sekitar. Kadar penukaran fotoelektrik adalah sehingga 25-30%. Penggunaan kuasa elektrik yang rendah, hanya kira-kira 20% -30% mesin pemotong laser CO2 tradisional.

6. Penyelenggaraan yang rendah: penghantaran talian gentian tidak memerlukan lensa, menjimatkan kos penyelenggaraan;

7. Mudah Operasi: penghantaran gentian talian, tiada penyelarasan laluan optik.

Butiran Cepat

Keadaan: Baru

Jenis Laser: Serat Laser

Bahan yang berkenaan: Logam

Pemotongan Ketebalan: Bergantung

Kawasan Memotong: 1500x3000mm

Kelajuan Pemotongan: 500mm/s

CNC atau Tidak: Ya

Mod Penyejukan: Penyejuk Air

Perisian Kawalan: BodorPro

Format grafik yang disokong: AI, BMP, DXF, PLT

Pensijilan: CCC, CE, ISO, SGS, UL

Perkhidmatan selepas jualan yang disediakan: Jurutera yang tersedia untuk jentera perkhidmatan di luar negara

Kata kunci: mesin pemotong laser logam jualan panas

Ketebalan memotong: 0-30mm

Ketepatan kedudukan: 0.02mm

Kelajuan pemotongan: 0-10000mm/min

Bahan pemotongan: Keluli tahan karat logam aluminium keluli karbon

Permohonan: Lembaran Aluminium

Kaedah tindakan ragum: Ragum Pengapit Separa Automatik

Kuasa: Mekanikal

Jenama: bodor

industri: barang kemas barangan logam alat ganti kereta

Bahagian Mesin

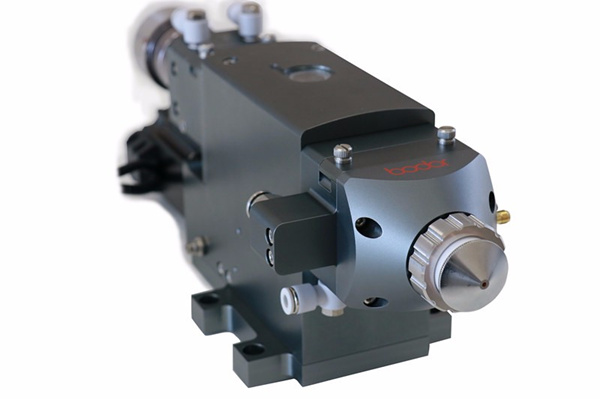

Nama: Kepala Laser Fokus Auto BodorGenius

1,AutoFokus

Terpakai kepada pelbagai fokus panjang, yang dikawal oleh sistem kawalan alat mesin. Titik fokus akan diselaraskan secara automatik dalam proses pemotongan untuk mencapai kesan pemotongan yang terbaik dari ketebalan logam lembaran yang berbeza.

2, Bebaskan Tangan Anda

Panjang fokus dikawal oleh sistem pengendalian. Kami tidak perlu melakukan peraturan manual, yang berkesan mengelakkan ralat atau kesalahan yang disebabkan oleh operasi manual.

3, cepat

(1) Fokus automatik akan melaraskan titik fokus yang paling sesuai secara automatik dalam proses tebukan dan pemotongan, yang meningkatkan kelajuan pemotongan dengan ketara;

(2) Apabila menggantikan bahan yang berbeza atau kepingan ketebalan yang berbeza, kepala laser fokus manual memerlukan peraturan manual, yang susah payah dan memakan masa; kepala laser fokus auto dikawal oleh sistem kawalan, ia boleh membaca parameter penyimpanan sistem secara automatik, menjimatkan masa dan tenaga kerja;

(3)Laci kanta pelindung collimating boleh melindungi kanta collimating dengan lebih baik dan meningkatkan kelajuan penggantian kanta pelindung.

4, Ketepatan

Meningkatkan panjang fokus perforasi, secara berasingan menetapkan panjang fokus perforasi dan memotong panjang fokus, meningkatkan ketepatan pemotongan.

5, tahan lasak

(1) Struktur penyejukan air berganda terbina dalam boleh memastikan suhu malar komponen kolimat dan fokus, mengelakkan kerosakan kanta yang terlalu panas, kesan penyejukan adalah lebih baik, tiada pemanasan atau fogging dalam pemotongan jangka panjang, hayat perkhidmatan kanta telah dipanjangkan.

(2) Meningkatkan kanta pelindung collimation dan fokus kanta pelindung, berhati-hati melindungi komponen utama.

Nama: Badan Mesin Casting Bersepadu

Menggunakan besi tuang grafit serpihan, kekuatan tegangan terendah ialah 200MPa. Kandungan karbon yang tinggi, kekuatan mampatan yang tinggi dan kekerasan yang tinggi. Penyerapan kejutan yang kuat dan rintangan haus. Kepekaan terma yang rendah dan sensitiviti jurang katil mengurangkan kehilangan peralatan dalam penggunaan, jadi ketepatan mesin dapat dikekalkan untuk jangka masa yang lama, dan tiada ubah bentuk dalam kitaran hayat.

Nama: Kabinet kawalan

Sumber laser bersepadu dan semua bahagian mesin elektronik, kabinet boleh melindungi bahagian elektrik berharga dan sumber laser mahal. Kipas dalam kabinet menyediakan sistem penyejukan yang lebih baik untuk bahagian elektrik

Nama: Sistem pelinciran automatik

Pelinciran elektrik ialah sejenis pam gear dengan pembinaan rasional, prestasi hebat dan fungsi komprehensif.

Dengan sambungan dengan sistem kawalan program dalam mesin utama, sistem pelinciran boleh mengawasi paras minyak dalam tangki serta tekanan penghantaran minyak dan menetapkan berkala pelinciran, yang secara berkesan akan menghalang karat dalam sistem pelinciran untuk memastikan ketepatan pemotongan.